- +31 (0)857 859 844

- info@techflex.nl

- Prijzen excl. BTW

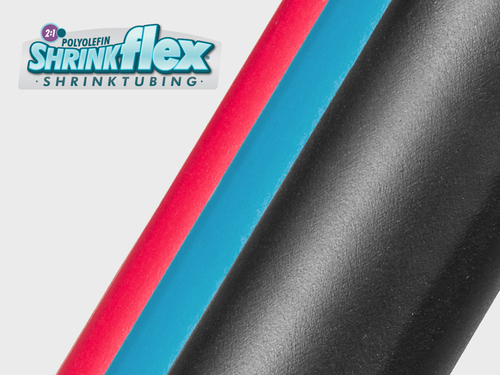

Krimpkousen zijn ideaal voor het creëren van een strakke, professionele uiteinde op elke draad, slang of kabel management project.

Economisch en eenvoudig te installeren krimpkous

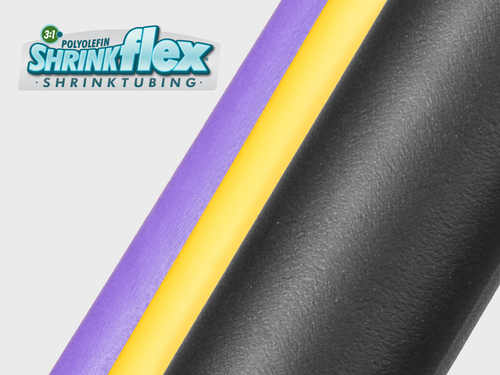

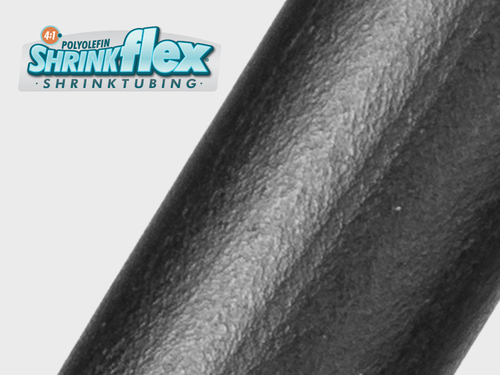

Economisch en eenvoudig te installeren krimpkous krimpt tot 1/3 van de oorspronkelijke diameter!

Krimpt eenvoudig over grote connectoren en stekkers

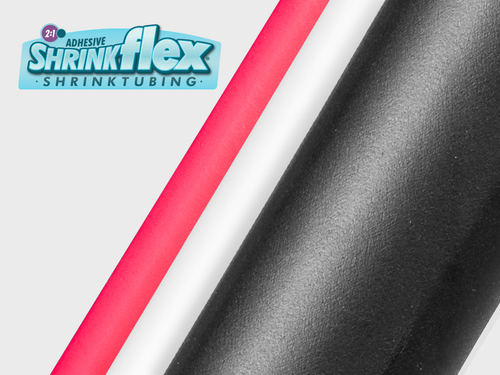

Dubbelwandig met lijm gevoerde polyolefin krimpkous

Dubbelwandig met lijm gevoerde polyolefin krimpkous

Weerbestendige dubbelwandig met lijm gevoerde krimpkous

Zeer heldere krimpkous voor het afwerken van bedrading

Een aantrekkelijke glossy afwerking voor elke afwerking

Krimpkous die bestand is tegen extreme temperatuurschommelingen

Rubberachtig, vloeistofbestendig, vlamvertragende krimpkous

Vlamvertragende EMI afschermende dubbelwandige krimpkous

3:1 krimpkous met hoogfrequente EMI-afschermingseigenschappen

4:1 krimpkous met hoogfrequente EMI-afschermingseigenschappen

Laat uw krimpkous op maat snijden en bedrukken met uw eigen design

Vragen? Wij staan altijd voor u klaar